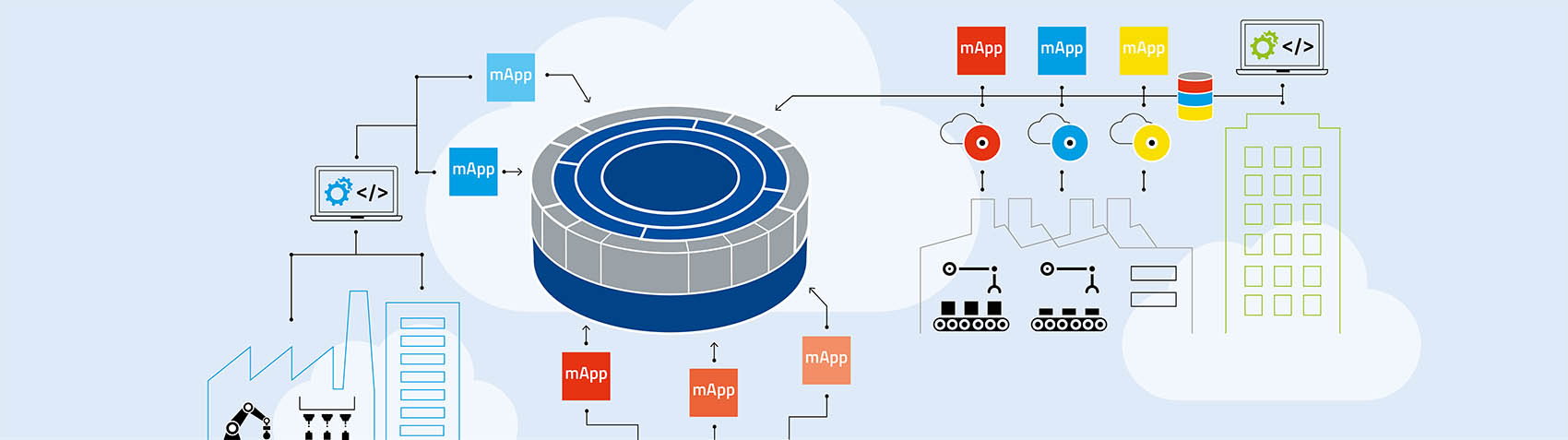

Manufacturing Integration Platform (MIP)

Manufacturing Apps (mApps) from the ecosystem for manufacturing IT

Manufacturing companies need a wide range of IT applications in order to plan and produce efficiently. MPDV's open platform concept, the Manufacturing Integration Platform (MIP), offers the opportunity to combine so-called mApps from different providers as desired. This combination creates an ecosystem which generates great benefits for both manufacturing companies and developers, system integrators and machine manufacturers. The vendor lock-in effect customary in manufacturing IT to date is completely eliminated by the MIP. The MIP as the functional infrastructure of the Smart Factory gives manufacturing companies maximum flexibility while relying on a future-proof IT architecture.