Find out how you can digitalize your production

with solutions from MPDV!

Lean methods – Smart Factory Glossary

Lean methods are structured approaches that aim to make company processes more efficient, minimize waste and maximize value for the customer. They are central components of lean management, which focuses on increasing competitiveness through continuous improvement and the involvement of all employees.

Various lean methods are presented in detail below. They support companies in optimizing their processes and establishing a culture of continuous improvement.

5S method - Seiri, Seiton, Seiso, Seiketsu, Shitsuke

The 5S method is an approach to organizing and optimizing workplaces. The lean management method is used in production and in the office.

The 5S method consists of five steps:

- Seiri – sort out: All work equipment at the workplace is viewed and sorted into necessary and unnecessary items. This creates space and optimizes the working environment.

- Seiton – place (systematize): All remaining work equipment is arranged at the workstation according to ergonomic principles so that it is easily accessible. The locations of the work equipment are marked.

- Seiso – clean: The workplace is cleaned regularly to ensure cleanliness and order.

- Seiketsu - standardize: Standards and procedures are developed to maintain the first three steps.

- Shitsuke – self-discipline: Self-discipline is encouraged, and regular audits are to permanently integrate the 5S principles into the corporate culture.

Goal of the 5S method:

The main aim of 5S is to create a clean, safe and efficient working environment that minimizes waste and increases productivity and safety.

Advantages of the 5S method:

The advantages of the 5S method are manifold: it increases the efficiency of work processes, minimizes search times, reduces errors, speeds up workflows and improves occupational safety. A clean, well-organized workplace also promotes a good working atmosphere and employee motivation, which ultimately increases the quality of work results. Overall, the lean method contributes to the optimal use of resources and continuous improvement of production processes.

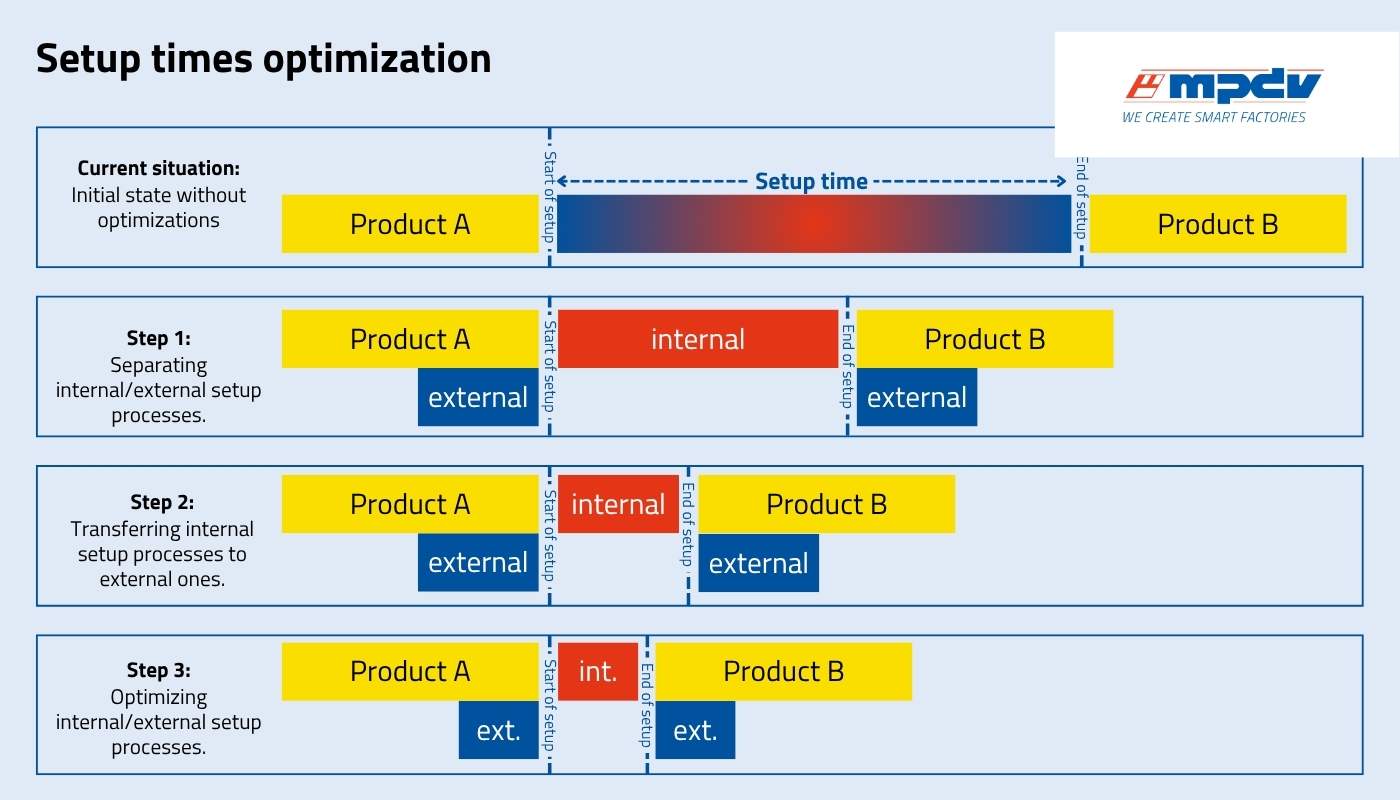

SMED – Setup time optimization

SMED is a lean method that aims to significantly reduce the set-up times of machines and production lines. The abbreviation stands for Single Minute Exchange of Die and literally means "tool change in the single minute range". SMED was developed by Shigeo Shingō as part of the Toyota Production System.

SMED is implemented in several steps:

- As-is analysis: Current set-up processes are recorded and evaluated to identify inefficient processes and fluctuations in set-up times.

- Separation of set-up processes: Distinction between internal and external set-up processes. Internal set-up processes can only take place when the machine is at a standstill, external set-up processes during operation.

- Transfer from internal to external set-up processes: Where possible, internal set-up steps are redesigned so that they can be carried out externally to minimize downtimes.

- Optimization and standardization: Set-up processes are improved and standardized through organizational and technical measures. Organizational optimization techniques include, for example, preparing the production changeover while the machine is still running or optimizing the workplace using the 5S method. The use of quick-clamping devices to speed up tool changes or the use of modular tool systems are among the technical measures.

- Elimination of adjustments: Precise settings during the adjustment process prevent readjustments.

Goal of SMED:

The main aim of SMED is to convert machines to new production processes in less than ten minutes so as not to disrupt the production flow and increase flexibility. This enables a rapid response to market requirements and supports the production of small batch sizes.

Advantages of SMED:

By applying the SMED method, companies can make their production processes more efficient, increase their competitiveness and respond better to individual customer requirements.

- Smaller batch sizes: Enable more frequent product changes and a greater variety of products.

- Lower inventories: Reduced storage costs and space requirements thanks to smaller batch sizes.

- Shorter throughput times: Increased productivity through minimized downtimes.

- Increased flexibility: Quicker response to customer requirements and improved adherence to deadlines.

- Fewer start-up losses: Faster production start-up with defect-free parts reduces rejects and rework.

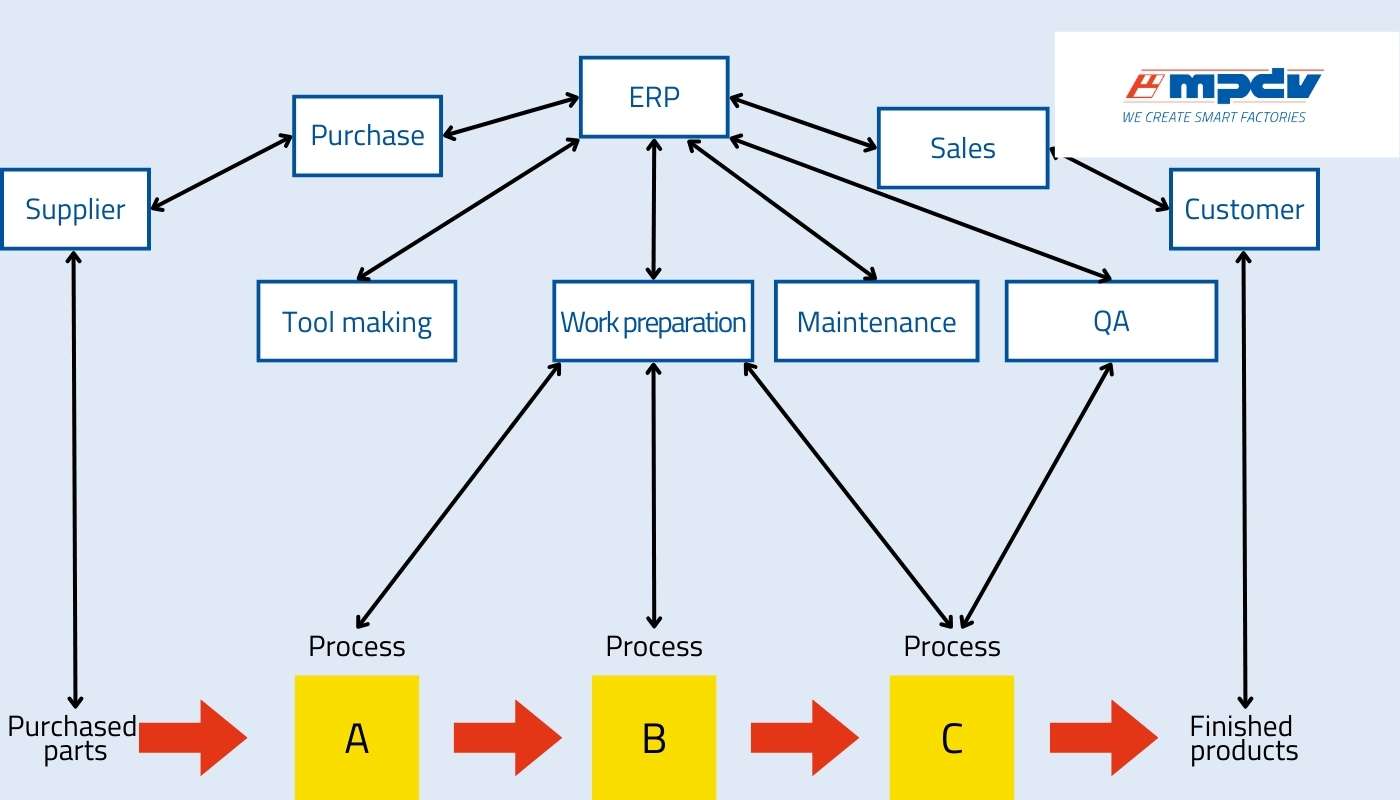

Value stream mapping – Recording production processes

Value stream mapping is a method for the detailed recording and visualization of current production processes. It includes the manufacturing and planning processes, information and material flow as well as the IT systems. The method records the current situation in production with the utmost precision. This is comparable to an X-ray image on which every little detail is visible. The complex structures that have developed over the years become visible; potential opportunities in administration, production, and IT can be identified on this basis and subsequently optimized.

As part of the value stream analysis, production processes of individual products and supporting functions are recorded and visualized in a value stream diagram. This approach considers the entire material flow from the ordering of raw materials through the processing steps to the dispatch of the finished product. In addition, all information flows and planning processes from receipt of the customer order through production planning and control to production are included.

Aim of the value stream analysis:

The aim of value stream mapping is to identify weak points and potential to eliminate non-value-adding processes and reduce waste in line with lean management.

Advantages of value stream mapping:

- Objective determination of the initial situation: Transparent presentation of the current production status, including weak points and opportunities for improvement.

- Identification of strategic potential: Recognizing opportunities for the strategic orientation of the company based on a comprehensive overview.

- Increased acceptance in the departments: Integrated value stream management promotes the acceptance of the departments involved.

- Transformation to a Smart Factory: Based on the value stream analysis, companies can take steps to transform their factory into a smart factory.

- Increased efficiency: The use of systems such as Manufacturing Execution Systems (MES) increases transparency in production, reduces paperwork and increases efficiency.

Kaizen – Continuous improvement

Kaizen is a lean concept that focuses on continuous improvement through small, incremental changes. The method is also known as the Continuous Improvement Process (CIP), as the focus is on the continuous pursuit of improvement and perfection. Kaizen promotes a corporate culture of continuous learning, collaboration and the involvement of all employees in the improvement process. The work philosophy is used in business processes and quality management, for example. The term is made up of the Japanese words “kai” (改 = change) and “zen” (善 = good) and means improvement or change for the better.

The goal of Kaizen:

The aim of Kaizen in the production environment is to increase efficiency, improve quality, and make optimum use of resources through continuous improvements. It encourages all employees to actively participate in the improvement of processes and workflows.

Advantages of Kaizen:

The benefits of Kaizen include increased productivity, improved quality of products or services, as well as increased employee commitment and satisfaction. It enables companies to adapt flexibly to market changes and strengthen their innovative power.

Kanban – Process control

Kanban is a process control method. The Kanban method aims to produce or provide only the quantities of materials required in order to minimize excess stock and increase flexibility. The Kanban method structures the production of goods in manufacturing processes that work according to the just-in-time (JIT) principle. This means that the raw material required for production is provided at exactly the right time.

The method is often used as part of lean management and has its origins in the Toyota production system. Kanban was originally developed as a visual system to control material flows and production processes - without being dependent on IT systems. To this end, self-controlling Kanban control loops with Kanban cards are installed in production: Employees can see at any time which item they need to produce and in what quantity.

The word Kanban comes from the Japanese and means something like card, board or receipt. In practice, Kanban uses cards or boards, for example, to visualize the progress of tasks and to identify and eliminate bottlenecks in the production process.

Goals of Kanban:

The main objective of Kanban in a lean management context is to improve production processes in order to

- increase efficiency,

- increase flexibility,

- reduce waste,

- respond more quickly to customer requirements,

- to ensure a continuous flow in production.

By visualizing workflows, Kanban enables teams to identify bottlenecks early and adjust processes accordingly to ensure a more even workload. This not only leads to higher productivity, but also to better quality products and services.

Advantages of Kanban:

The advantages of Kanban for manufacturing companies lie in the increased efficiency and flexibility of production processes. As stock levels and waiting times are reduced, the supply chain can be optimized and lead times significantly shortened. Kanban also promotes a culture of continuous improvement: employees are encouraged to proactively look for ways to optimize processes.

Poka Yoke – Avoid mistakes

Poka Yoke is a quality management method that aims to prevent and immediately correct errors in processes. Poka Yoke specifically supports employees in the production process in avoiding errors when operating systems. Time-consuming quality checks afterwards are minimized.

The lean technique often uses simple, visual aids to avoid (careless) errors.

- Color-coded components: Different parts are color-coded - this guarantees that the parts are assembled correctly (e.g. red plug into red socket).

- Visible fill level markings: Transparent containers with markings indicating the optimum fill level - this avoids overfilling or underfilling.

- Checklists and diagrams: Visual representations of work steps attached to workstations - this ensures that no steps are overlooked.

- Molds and templates: Tools or parts with unique shapes that only fit in a specific alignment - this prevents incorrect insertion.

- Traffic light systems: Lights or displays that show a process or machine status in red, yellow and green - this immediately draws attention to a problem.

- Visual warnings: Stickers or symbols that indicate hazards - this provides important information for safe operation.

Objectives of Poka Yoke:

The aim is to identify sources of error and design processes in such a way that human errors are avoided or immediately recognizable. This leads to improved product quality and increases customer satisfaction.

Advantages of Poka Yoke:

The method offers numerous advantages, including

- Reduction of rejects and rework costs

- Promotion of error-free production

- Increased efficiency

- Increased process reliability

- Less training required for employees

Six Sigma – Process effectiveness

Six Sigma is a lean method for process improvement based on statistical analyses. Six Sigma is also known as 6σ. The term "Six Sigma" is derived from the statistical symbol for standard deviation. The method consists of five phases, known as DMAIC, which is derived from the initial letters of the English terms:

- Define: Define problems and goals

- Measure: Collect and analyze data

- Analyze: Identify causes for errors

- Improve: Develop solutions

- Control: Ensuring the sustainability of improvements

The goal of Six Sigma:

The aim is to achieve virtually error-free processes and increase quality.

Advantages of Six Sigma:

By implementing Six Sigma, organizations can achieve significant improvements in efficiency, quality, and financial results. Some of the key benefits of Six Sigma are:

- Error reduction: Six Sigma aims to reduce the number of errors and defects in processes, which leads to higher quality and customer satisfaction.

- Cost reduction: By improving process efficiency and reducing errors, companies can lower their operating costs.

- Data-driven decisions: The methodology uses statistical analysis to make informed decisions, which increases the accuracy and effectiveness of improvement measures.

- Strategic alignment: The methodology helps companies to better align their processes with their strategic goals, which improves overall performance.

- Flexibility: Six Sigma can be applied in different industries and departments, making it a versatile tool for process improvement.

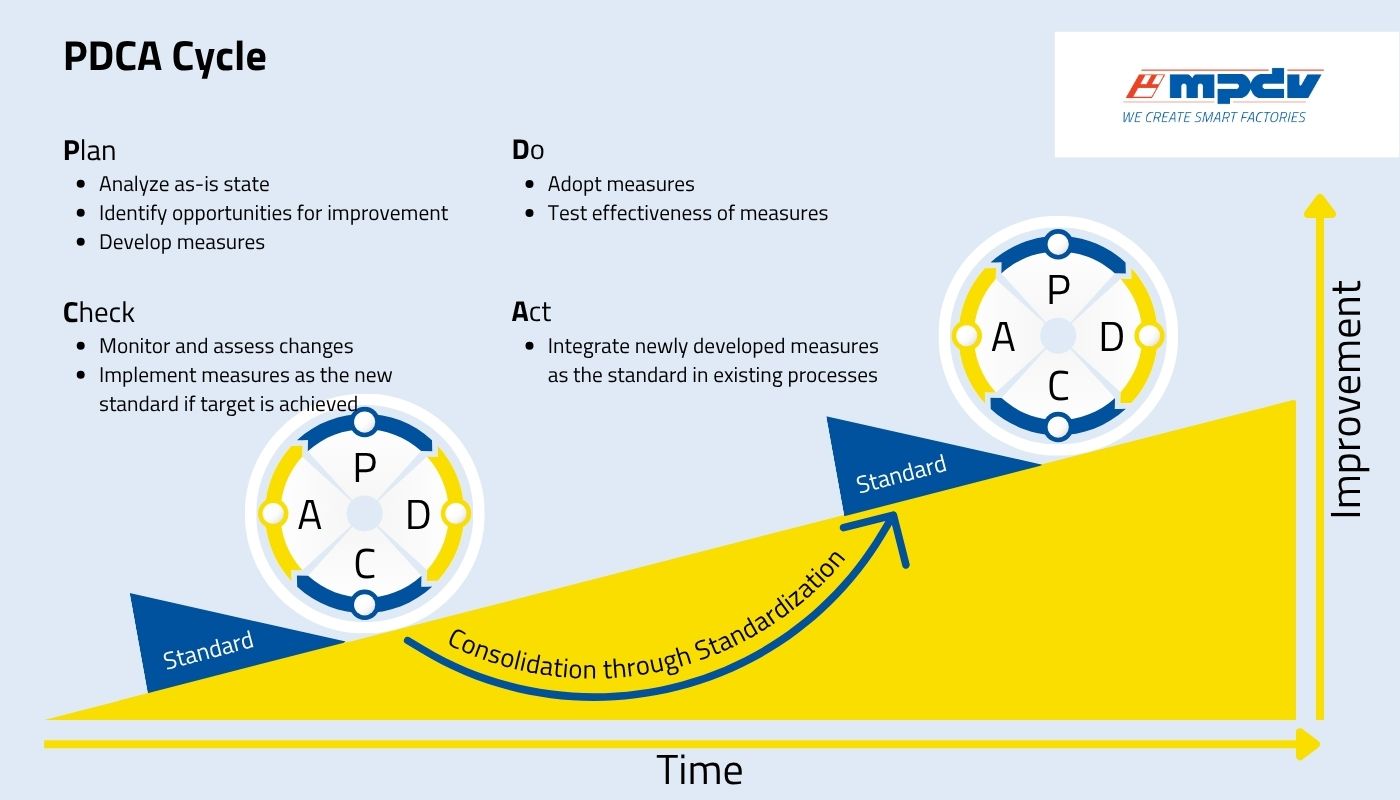

PDCA cycle – plan, do, check, act

The PDCA cycle is an iterative method for the continuous improvement of processes and products. The management cycle consists of the four phases Plan, Do, Check, Act, from whose initial letters the name is derived.

Goal of the PDCA cycle:

The method is used by companies to systematically identify problems, test solutions, and implement sustainable improvements.

Advantages of the PDCA cycle:

The PDCA approach promotes a structured approach, makes it possible to identify errors at an early stage and react flexibly to changes. It also supports learning from experience and promotes a culture of continuous improvement.

Just-In-Time (JIT) – optimize warehouse and material delivery

Just-In-Time (JIT) aims to optimize the production process by minimizing inventory and delivering materials and products on time. JIT focuses on producing exactly what is needed, in the right quantity and where it is required. This is achieved by designing supply chains and production processes to be flexible and responsive to changes in demand.

Goals of Just-In-Time:

The main goal of JIT in lean management is to increase efficiency by reducing waste, including excess inventory, waiting times and overproduction. By implementing the Just-In-Time lean method, companies can reduce lead times, improve quality, and increase customer satisfaction.

Advantages of Just-In-Time:

The JIT method offers several advantages for manufacturing companies:

- Reduced storage costs: As materials and products are only ordered and produced when required, the need for storage space for temporary storage is reduced, which lowers warehousing costs.

- Less capital tied up: companies need to invest less capital in inventories, which leads to better liquidity and capital utilization.

- Reducing waste: JIT promotes continuous improvement and efficiency by minimizing overproduction, waiting times, and excess inventory.

- Improved quality: As the focus is on the production of smaller batches, quality problems can be identified and rectified more quickly before they affect larger parts of production.

- Faster time to market: Producing in smaller batches and minimizing lead times allows companies to react more quickly to market changes and launch new products faster.

Despite all the benefits, however, it should not be forgotten that JIT can also bring challenges. These include dependence on reliable suppliers and vulnerability to disruptions in the supply chain. Careful planning and implementation are crucial to fully exploit the benefits of just-in-time.

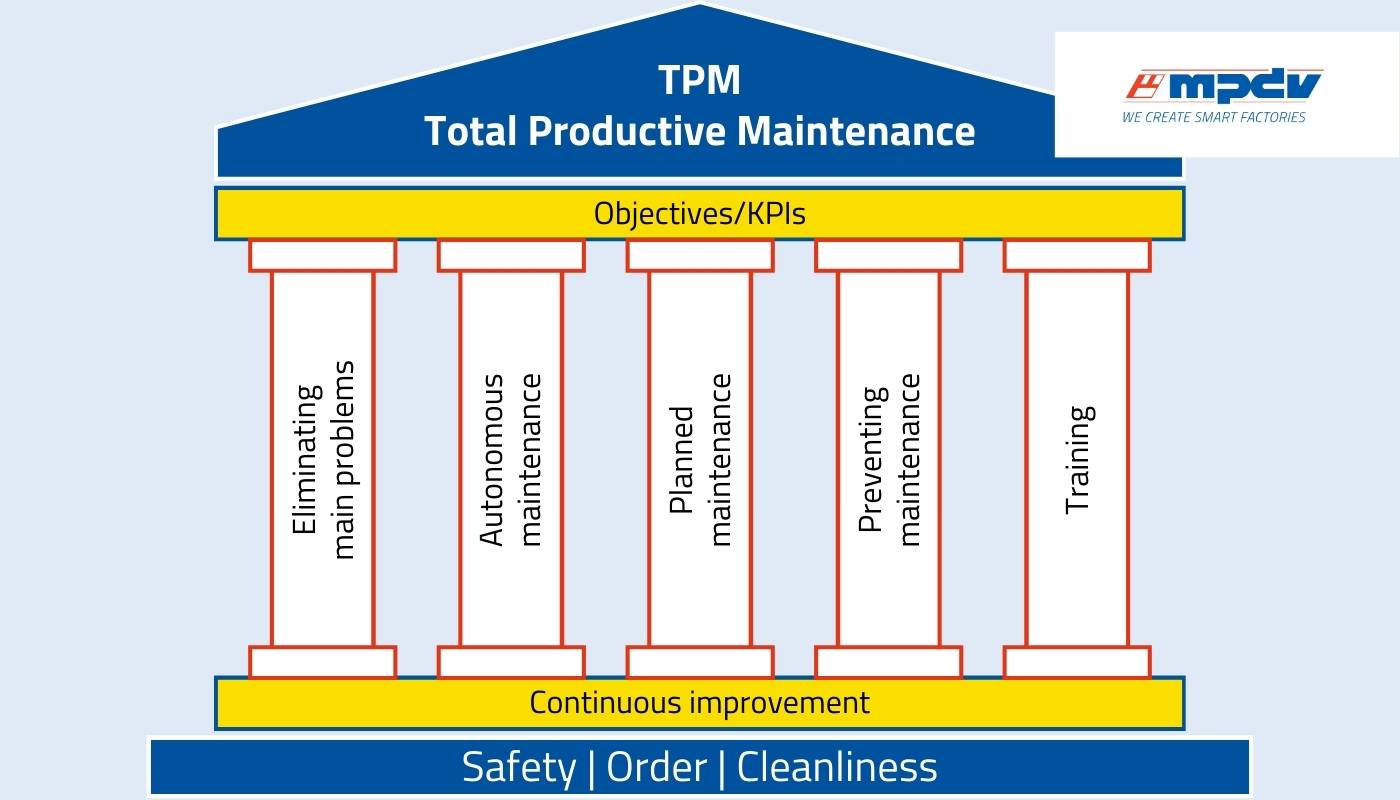

Total Productive Maintenance (TPM) – Preventive maintenance

Total Productive Maintenance (TPM) is a lean management method that aims to maintain machines through preventive maintenance strategies and minimize unforeseen downtime. A central element of TPM is close cooperation between different departments, with all employees actively involved in the maintenance process.

The five pillars of Total Productive Maintenance:

- Elimination of center of primary problems: Identifying and solving fundamental problems that affect the efficiency and performance of machines.

- Autonomous maintenance: Machine operators perform basic maintenance tasks such as cleaning and inspection to detect signs of wear at an early stage.

- Planned maintenance: Regular, carefully planned maintenance work reduces unplanned machine downtimes and extends the service life of machines.

- Maintenance prevention: Consideration of subsequent maintenance when purchasing and installing machines, e.g. through good accessibility to all maintenance points.

- Education and training: Continuous development of employees through targeted training to strengthen their skills in machine operation, maintenance and problem solving.

Eight basic principles are also frequently cited as the foundation of the TPM method: autonomous maintenance, continuous improvement, planned maintenance, quality management, equipment management, training and further training, occupational health and safety, and TPM in administrative processes.

Goals and advantages of Total Productive Maintenance:

The main aim of TPM is to increase the availability of production facilities, measured in terms of Overall Equipment Effectiveness (OEE).

- Machine availability: Systematic maintenance and preventive maintenance maximize machine uptime and reduce unplanned downtime.

- Plant efficiency: Continuous monitoring and targeted improvement measures increase the overall effectiveness of the plant.

- Manufacturing defects: Integrating quality management practices ensures that machines produce high quality products without defects, reducing rework and scrap.

- Occupational safety: Regular inspections of machines and systems help to identify and eliminate potential hazards, which contributes to a safe working environment.

- Employee participation: Employees' skills are developed through continuous training so that they can actively contribute to the maintenance of the machines.

Hoshin Kanri – Efficient strategy implementation

Hoshin Kanri is a lean method that aims to align a company's strategic direction with its operational activities. The method uses a systematic, structured approach to ensure that all employees are working towards the same goal and that the company's long-term strategic objectives are translated into concrete, actionable measures. It requires a planning process that sets a clear direction and includes a concrete implementation plan. As part of the continuous improvement process, implementation is constantly readjusted.

The term is derived from the Japanese, hoshin meaning clear direction or guideline. Kanri refers to the implementation plan or management.

Aim of Hoshin Kanri:

The main objective of Hoshin Kanri is to establish a clear link between strategic planning and the day-to-day work within an organization. This method helps companies to focus on their most important goals and ensure that all levels of the organization are involved in achieving these goals.

Advantages of Hoshin Kanri:

Hoshin Kanri offers numerous benefits, including:

- It helps to set clear goals and ensure that all employees understand the corporate strategy and are involved in its implementation.

- Through regular feedback loops, Hoshin Kanri improves communication within the organization and promotes a culture of transparency and collaboration.

- The lean method helps companies to focus on the most important strategic initiatives and deploy resources in a targeted manner.

- Hoshin Kanri promotes a culture of continuous improvement by facilitating regular reviews and adjustments to strategic plans.

Heijunka – Harmonized production process

Heijunka is a basic lean principle in which the production flow is smoothed and harmonized in flow production. It refers to the even distribution of production and labor to maintain a constant flow rather than reacting to short-term peaks or troughs in demand. Wait and transportation times are avoided wherever possible.

The term Heijunka comes from the Japanese and means leveling.

Destination of Heijunka:

The main goal of Heijunka is to level production so that workloads are evenly distributed, and resources are optimally utilized. This minimizes the need to react to last-minute changes and helps to ensure a stable and predictable production process.

Advantages of Heijunka:

One of the most important benefits of Heijunka is the reduction of waste, as overproduction and unnecessary stock levels are avoided. In addition, consistent production leads to better utilization of labor and machinery, which reduces operating costs. Another benefit is the improvement in customer satisfaction, as Heijunka makes it possible to meet more reliable delivery times and respond more quickly to customer requests.

Muda, Mura, Muri – Toyota 3M model

The Toyota 3M model aims to increase efficiency and minimize waste in production processes. The three Ms stand for Muda (waste), Mura (inconsistency) and Muri (overload). Each of these elements addresses specific challenges in production. By eliminating these factors, companies can optimize their processes and improve the quality of their products.

Muda – Waste

Muda stands for waste and refers to any activity or resource that does not add value to the end product, i.e. any non-value-adding activity in the production process. Seven types of waste are identified in the Toyota Production System:

- Overproduction: Production of semi-finished or finished products that are not needed. This places an unnecessary burden on production.

- Waiting times: Delays due to missing material, tools or unsuitable operating resources. This can lead to downtime.

- Unnecessary transportation: Unnecessary material movements between departments that do not create added value for the customer.

- Excessive machining: Complex processes and inadequate product design. This can impede the production process.

- Unnecessary inventories/storage: Superfluous inventories that tie up capital, cause follow-up costs and cover up weak points as a production buffer.

- Unnecessary movements: Lack of ergonomics in the workplace that requires additional movements, such as fetching tools and materials.

- Defects/rework: Defective products that cause additional costs due to inspection, rework, and post-production.

The aim is to identify and eliminate this waste to increase efficiency and reduce costs. Muda can be successfully reduced through continuous improvement and optimization of processes.

Mura – Irregularity

Mura stands for unevenness and describes the deviations in production processes that can lead to inefficiencies. These variations can be caused by unpredictable fluctuations in demand, inadequate planning or irregular production rates. Mura can lead to muri and muda if processes are not designed in a consistent and predictable way. Implementing standardization and creating a smooth flow in production are key measures to reduce mura. By smoothing production processes (see Heijunka), companies can be more responsive and flexible.

Muri – Overload

Muri means overload and refers to the overuse of staff, but also of other resources such as machines. When systems or people are stretched beyond their capacity limits, this can lead to errors, failures and an increase in operating costs. To avoid Muri, it is important to distribute workloads evenly and ensure that both human and machine resources are working at a sustainable pace. After all, if employees are overloaded, this can result in many sick days. By taking into account the capacities and limits of the production resources, the longevity and reliability of the entire system is improved.

Sources

- Production leveling: Wikipedia, 27.08.2024 [online] https://en.wikipedia.org/wiki/Production_leveling (accessed 24.03.2025).

- Hoshin Kanri: Wikipedia, 21.08.2024 [online] https://en.wikipedia.org/wiki/Hoshin_Kanri (accessed 24.03.2025).

- Lean manufacturing: Wikipedia, 21.03.2025 [online] https://en.wikipedia.org/wiki/Lean_manufacturing (accessed on 24.03.2025).

- Single Minute Exchange of Die: Wikipedia, 15.03.2025 [online] https://en.wikipedia.org/wiki/Single-minute_exchange_of_die (accessed on 24.03.2025).

- Value-stream mapping: Wikipedia, 24.02.2025 [online] https://en.wikipedia.org/wiki/Value-stream_mapping (accessed on 24.03.2025).

Would you like more information? We are happy to help.

Just fill in the form below. We will take care of your inquiry promptly.