Assembly Control

MPDV Mikrolab GmbH

Efficient assembly control

Assembly processes are often monitored and controlled by so-called head controls based on PLCs. With this type of control, every change must be programmed elaborately. Model-based assembly control with the mApp Assembly Control is much more flexible as the app contains all details in low code. The mApp manages process control including process interlocking and data collection with plausibility check. This means that all parts are processed and assembled according to specifications. Consistent data collection is used to document the manufacturing process. Traceability of your products is guaranteed at any time.

Optional functions

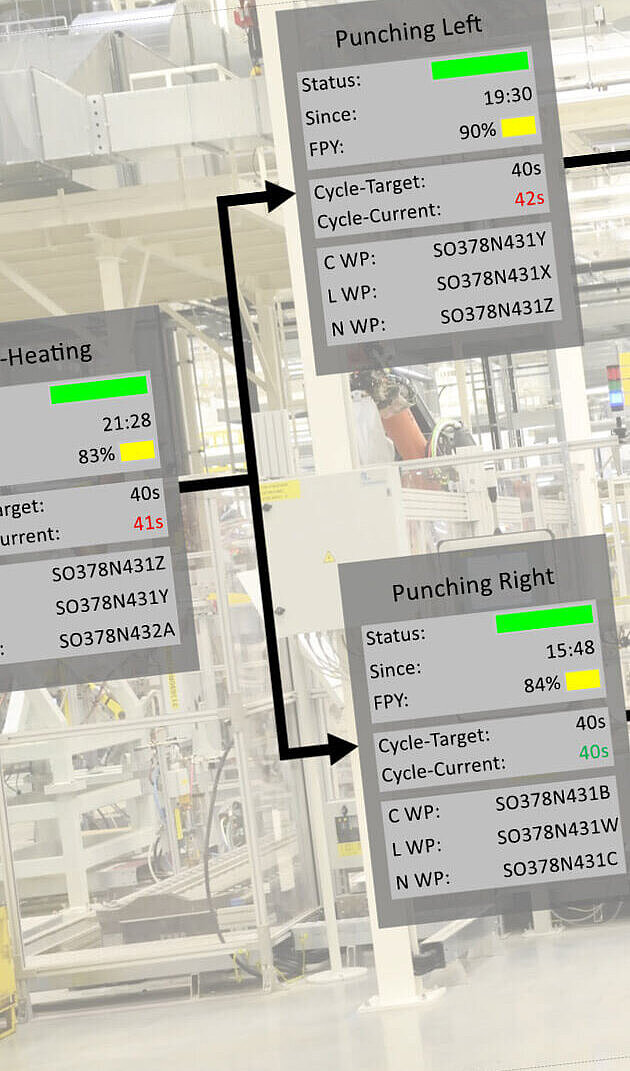

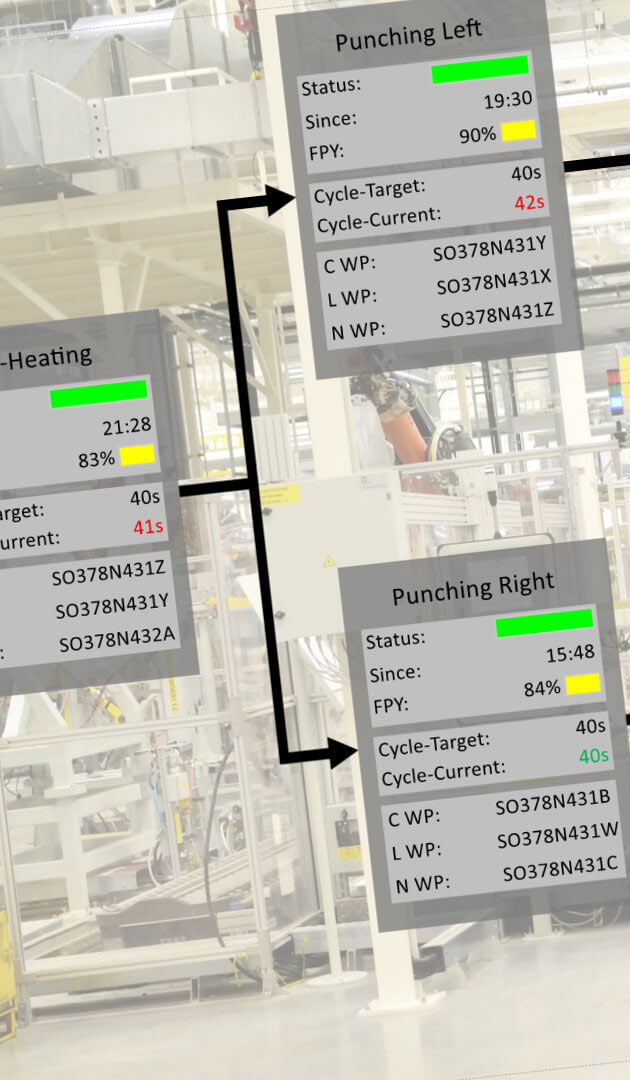

- Visualize statuses and malfunctions of separate workplaces and entire assembly lines

- First Pass Yield evaluation

Your benefits

You integrate your assembly processes into the manufacturing IT and thereby get access to critical data. The interaction of assembly with the rest of manufacturing increases the transparency and efficiency of your entire production. Changes to the manufacturing process can be modeled flexibly and cost-effectively.

Technical information

The mApp Assembly Control is part of the Assembly Management category of HYDRA X. Distributed Edge Computing (DEC) is used for data collection. The mApp uses data of the Virtual Production Reality (ViPR) of MPDV's Manufacturing Integration Platform (MIP).

Assembly Control in the MIP ecosystem

The mApp uses process models for assembly control, which are also employed for operator guidance. MPDV also offers the following mApps for this purpose:

- Production Process Modeling: digital mapping of assembly processes

- Operator Guidance: process-oriented operator guidance

#digitalization #assembly #smartfactory #dashboard #realtime #hydra