Initial sampling | QM.IS

Quality Miners GmbH

The optionally available CAD integration enables digital stamping of CAD drawings and ensures that there are no more transmission errors.

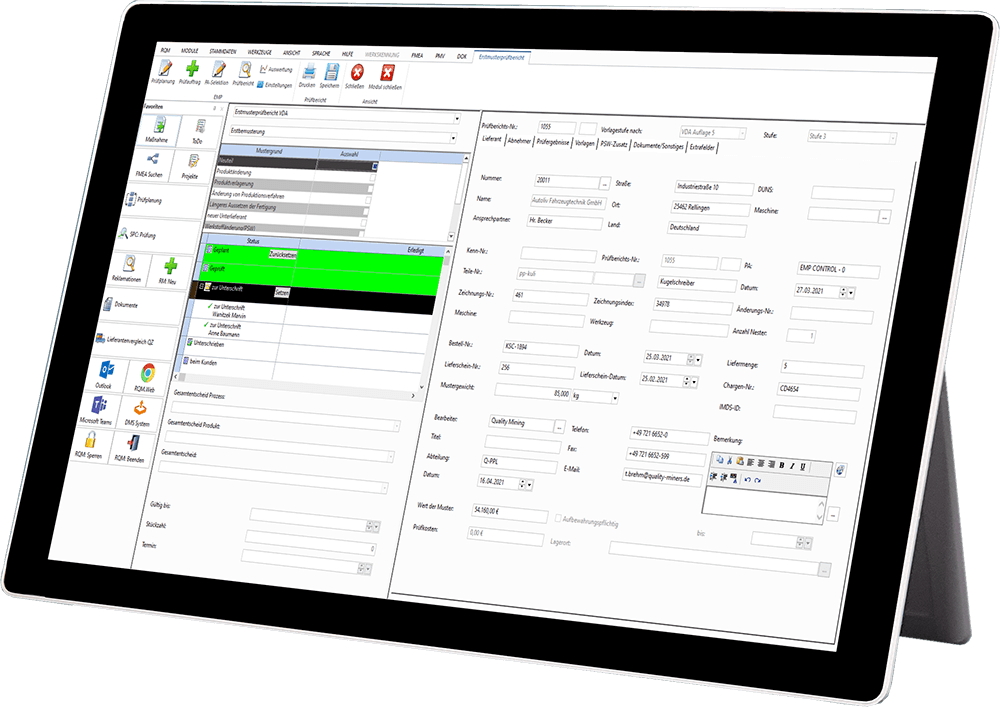

Initial sample inspection manages and monitors inspection steps and measures during the processing of new or modified parts. Simple and central management of template stages, template documents and PPAP documents goes hand in hand with fast test plan creation and initial sample inspection.

The initial sample inspection plans can in turn be used as a basis or template for subsequent inspection plans, e.g. in goods receipt or production. Initial sample inspection reports according to VDA or PSW are automatically created and sent at the push of a button. The resulting increase in on-time delivery and efficiency is the added value for the customer.

With the integrated stamping of CAD drawings and automatic test plan generation, the test planning effort is reduced by up to 80%.

In addition to high time savings and error-free data transfer, inspection planning and inspectors are supported with visual information for quality assurance.

Functions

- Support of inspection types and presentation stages according to VDA Volume 2.4

- Data import in QDX format possible

- Integration of any documents possible

- Automatic test plan creation from CAD files with stamping

- Automatically generated test reports

Your benefit

- Workflow control of the release processes via integrated action management

- Up to 80% time savings in inspection planning

- Automatic and fast generation of the inspection plan

- No media breaks or errors due to manual entries

- Automatically generated image sections for inspection in all areas

For more information about our QM.CAQ tools, please visit https://quality-miners.de/en/caq-software/.

#initial-sampling #ppap #vda-volume2 #caq