MDC with Auto-OEE Process Data

rwt GmbH

POiS® MDE ensures the automatic real-time collection of machine data, enables the identification of downtimes and provides comprehensive process data for analysis, optimization and post-calculation.

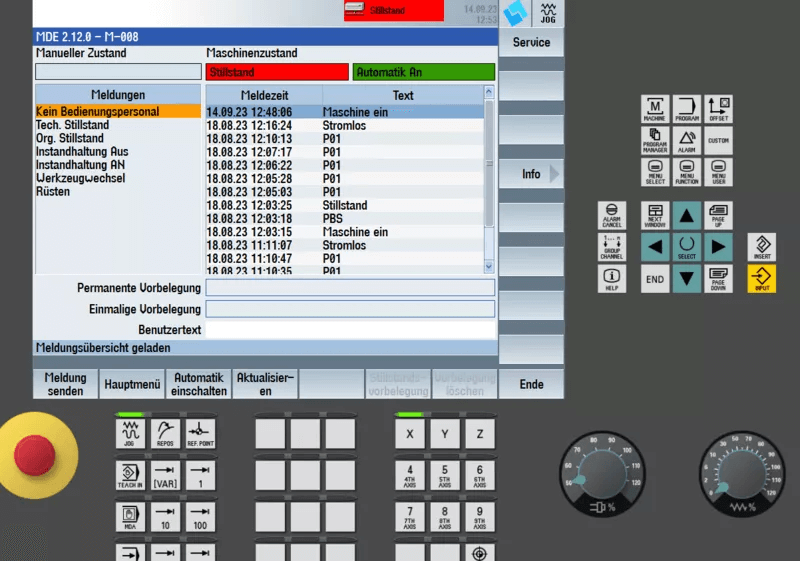

The integration of POiS® MDE directly into the CNC control ensures the exact recording of machine data and enables precise identification of the “production” status. If the reason for the machine standstill is not known, POiS® MDE actively prompts the machine operator for input from the CNC control system.

The recorded data is consistent, up-to-date and always available in real time for monitoring and analysis. Intelligent NC programs allow the production time of each individual workpiece to be reliably recorded. This real-time data provides important insights into deviations, process fluctuations and order progress and enables detailed article and OEE analyses - without the need for ODC. This serves to optimize ongoing processes as well as post-calculation and creates a basis for effective closed-loop manufacturing.