Find out how you can digitalize your production

with solutions from MPDV!

Four Building Blocks of a Perfect Production – Smart Factory Glossary

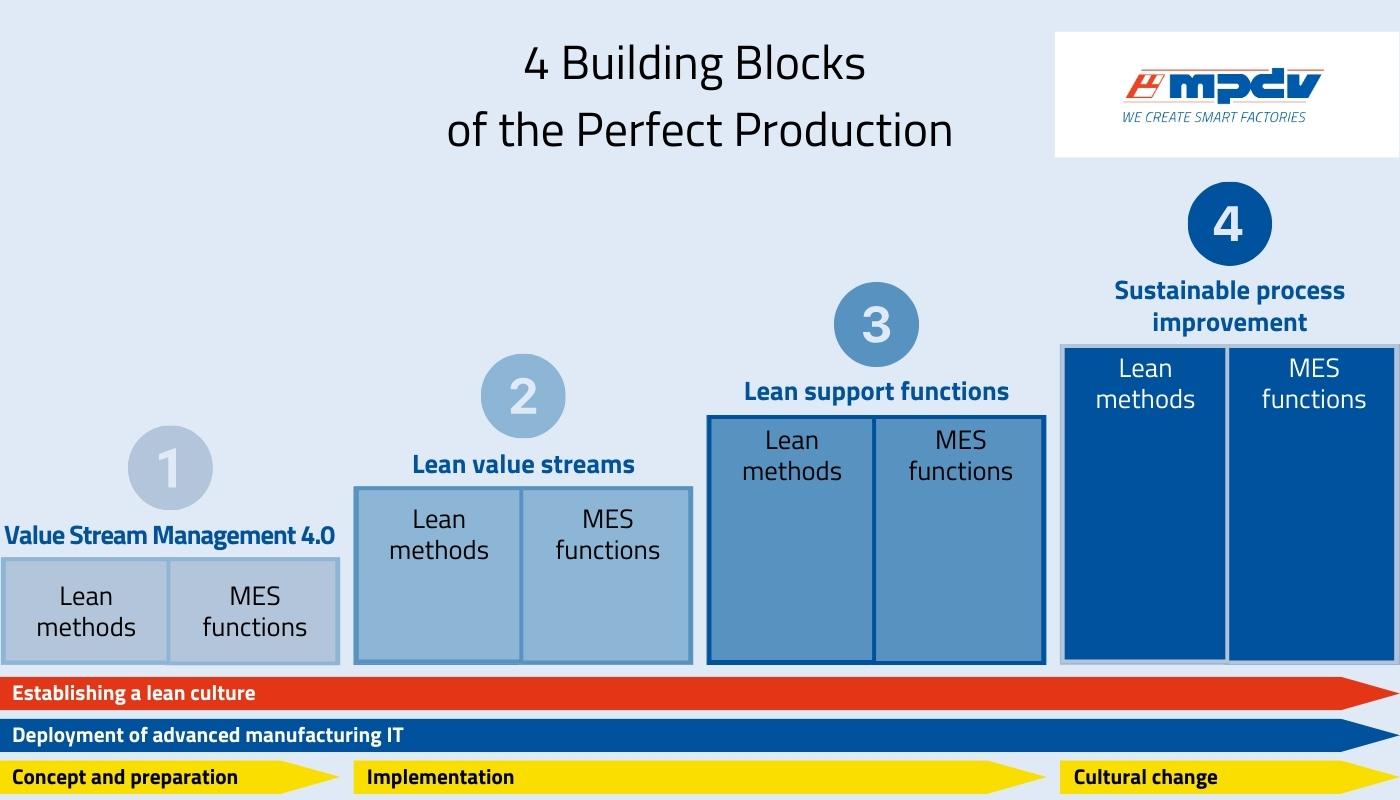

The hallmark of a perfect production process is efficiency, waste-free, and continuous optimization. To achieve this goal, companies must consistently improve their value streams, processes, and support functions. The four building blocks of perfect production help to accomplish this goal. These building blocks form an integrated concept that provides companies with comprehensive support in optimizing their production.

Combining lean methods with MES functions is the best way to pave the way for sustainable development towards perfect production.

Building block 1: Value Stream Management 4.0

The first and most important building block aims to precisely analyze the initial situation in production. The focus is on the manufacturing process, material flow, information flows, and planning processes. Another factor is how well individual areas are networked with each other. Information is visualized in a value stream map. To evaluate the information quickly, the value stream map is supplemented by a flow chart. This comprehensive chart can be used to identify potential improvements. The next step is to define the value stream design and following, to create the value stream design: a target concept is developed from the actual concept. The roadmap for implementing this target concept concludes the first of the four building blocks of a perfect production process.

Building block 2: Lean Value Streams

Lean production processes are the backbone of a production that can be quickly adapted. For this reason, lean management aims to avoid anything that could slow down a production process. The seven types of waste provide orientation: transportation, storage, redundant movements, waiting times, overproduction, inefficient processing, and failures. Reducing waste, optimizing production processes, and using lean methods such as one-piece flow or just-in-time can minimize throughput times and increase productivity.

Building block 3: Lean support functions

Efficient organization is needed not only for production itself, but also for production-related support functions such as rough and detailed planning. Digital assistance systems, automated workflows, and close networking between all areas help to ensure smooth processes. Even today, detailed scheduling for workplaces or machines is often done on the planning board in the supervisor's office or in Excel. Such processes are too slow to react immediately to changes, and sometimes production orders are created that cannot be realized. In this case, actual capacities and possible order backlogs in production are disregarded. An integrated planning tool from a manufacturing execution system (MES) can remedy this situation by enabling effective and realistic detailed planning that also factors in the availability of resources.

Building block 4: Sustainable process improvement

The first three building blocks are used to prepare measures for change and implement these. Once the processes have been streamlined using the right lean methods and digitalized with the help of key MES functions, building block 4 comes into play. Because perfection is not a state, but a continuous improvement process (CIP)! Only by continuously analyzing processes and embracing a culture of constant optimization can companies remain competitive and respond flexibly to change.

MPDV provides comprehensive support

The Executive Manufacturing Center (EMC) of MPDV assists companies in recording the actual state of production, defining a target state, and achieving and continuously improving this target state with suitable lean methods. MPDV also provides software solutions suitable for supporting lean methods and digitalizing the entire production process with its Manufacturing Execution System (MES) HYDRA X and the Advanced Planning and Scheduling System (APS) FEDRA.

Source

- Kletti, Jürgen/Rieger, Jürgen: Die perfekte Produktion ("The Perfect Production" only available in German). Manufacturing Excellence in der Smart Factory, 3. Edition., Berlin, Germany: Springer, 2022, p. 19, 51ff.)

Would you like more information? We are happy to help.

Just fill in the form below. We will take care of your inquiry promptly.