Find out how you can digitalize your production

with solutions from MPDV!

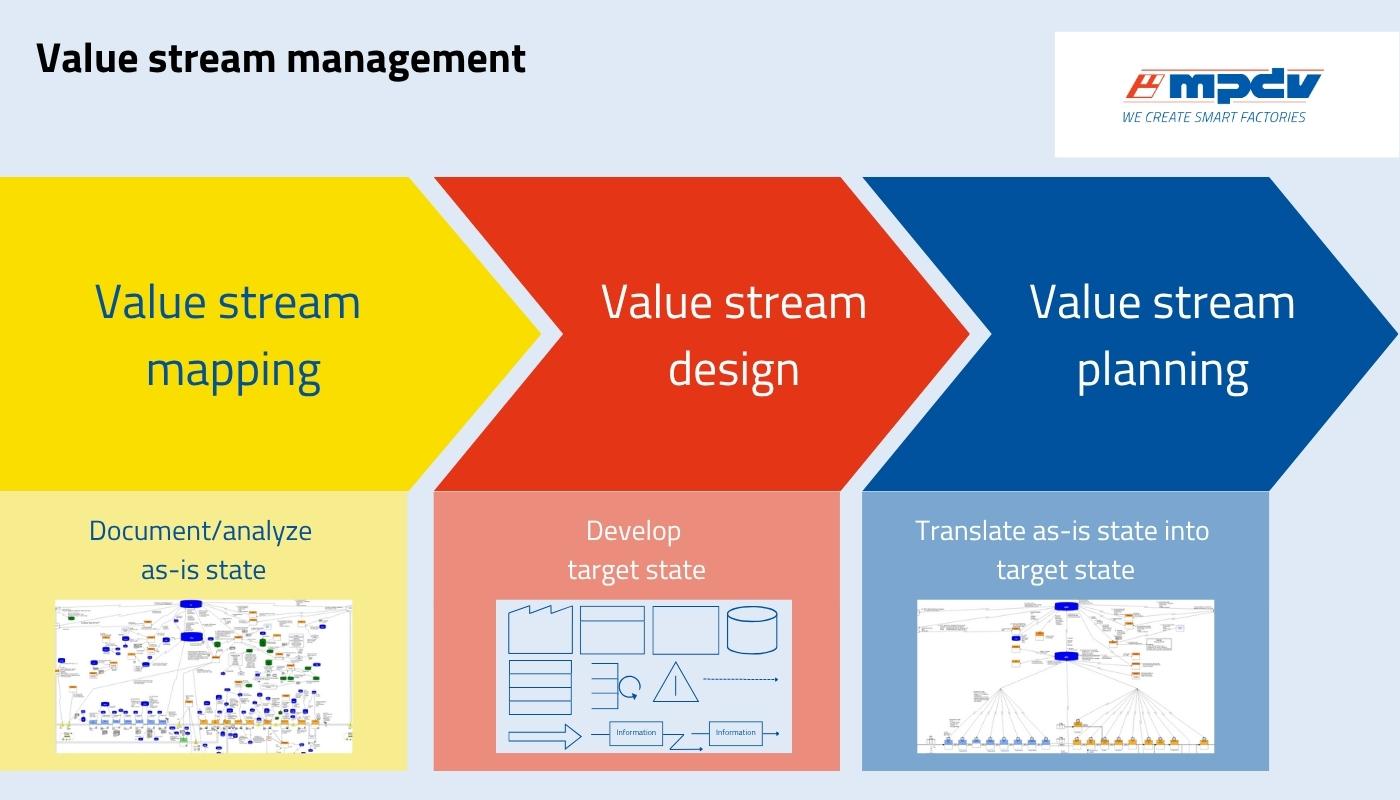

Value Stream Design – Smart Factory Glossary

Value stream design is a lean management concept dealing with the redesign of business processes. The concept refers to the restructuring and optimization of processes required to manufacture products or to provide services. The main focus is on making the entire production process more efficient by identifying and eliminating waste. The overall objective is to maximize value for the customer.

Value stream design builds on the findings of value stream mapping. In this case the entire value stream, i.e., all activities contributing to value creation are integrated and analyzed. A diagram, the value stream map, classifies all material and information flows in order for them to be optimized in the value stream design.

Main objectives of value stream design

In line with the lean philosophy, value stream design focuses on lean and efficient processes, continuous improvement, and the involvement of employees in the improvement processes. The following principles aim at optimizing core aspects of business performance:

- Reduce waste and thus costs: Eliminate unnecessary steps and resources, make better use of resources, save material costs.

- Shorten processes and thus production times: Speed up production and delivery times, increase flexibility, and adapt quickly to market changes and customer needs.

- Improve quality and thus customer satisfaction: Ensure consistently high product or service quality while aligning activities to maximize customer value.

The objectives vary from company to company and are derived from the overarching business strategy: if a company focuses on shortest possible delivery times, other processes are required than for a company committed to price leadership. In addition, key figures are essential for assessing whether the goals are being achieved.

Value stream design as part of value stream management

Value stream management is divided into value stream mapping, value stream design, and value stream planning, which is followed by a continuous improvement process. The value stream design only starts gradually, once basic questions on information flows, the planning process, the systems, and IT tools used have been clarified.

Analyzing the as-is state with value stream mapping

- Detailed recording and visualization of current process flows.

- Identification of bottlenecks, waste, and room for improvement.

Developing the target state with value stream design

- Definition of a perfect, optimized target value stream with improved processes.

- Specification of objectives and measures for improvement

- Definition of pull principles, cycle times, and lot sizes

- Application of lean principles, e.g., one-piece flow, kanban, supermarkets

Implementing measures with value stream planning

- Translation of the target state into specific measures and introduction of planned changes

- Definition of key performance indicators for success monitoring (e.g., lead time, inventories, value-added share).

- Training of employees and adaptation of processes.

Continuous improvement

- Regular review and adjustment of the value stream

- Implementation of a continuous improvement process (CIP).

Value stream design in detail

The current state of production has been documented and analyzed. The corporate strategy has been declared and the KPIs specified. Only now is the target state developed, i.e., the perfect value stream is designed.

- All-encompassing target concept: integrating the manufacturing process, material flow, information flow, planning processes, information on system support

- The target concept is refined iteratively: The process efficiency of the value stream is determined and compared with the as-is state. This allows the maturity of the target concept to be assessed and further adjusted if necessary.

- The target concept pursues value stream-related goals: complying with customer requirements, optimizing the material flow, cutting inventories, and reducing planning stages.

Methods and Tools

The key to success in value stream design is being aware of and knowing how to use lean methods and tools. Cleanliness (shine), order (set in order), and discipline (sustain) in accordance with the 5S method form the basis for further process optimization. You can use the following methods to achieve value stream-related goals:

- 5S method: workplace organization method to increase efficiency and safety.

- SMED (Single Minute Exchange of Die): reducing setup times

- Poka Yoke: avoiding failures through simple mechanisms.

- Kanban: controlling the material flow via visual signals.

- Kaizen: continuous, step-by-step improvement through small, incremental changes

Value stream design combines various lean methods to make the flow of materials and information more efficient and reduce waste. MPDV's Executive Manufacturing Center (EMC) helps companies optimize their production processes. A combination of lean methods and IT solutions makes the entire production process more efficient and maximizes the customer value. EMC develops customized digitalization strategies tailored to the company's specific requirements.

Source

- Value-stream mapping: Wikipedia, 24 February 2025 [online] https://en.wikipedia.org/wiki/Value-stream_mapping (requested on 19 March 2025).

Would you like more information? We are happy to help.

Just fill in the form below. We will take care of your inquiry promptly.